Currency

In the fields of mining crushing and large-scale construction material production, choosing a stable, efficient, and high-performance primary crusher is crucial to the success of any project. Among the heavy-duty crushers developed by Leimeng, the GC200 Jaw Crusher stands out with its superior handling capacity, rugged structure, and wide adaptability. It has become the preferred choice for professionals in the mining, metallurgy, cement, and construction industries worldwide.

This article provides a comprehensive analysis of the GC200 jaw crusher from multiple angles—including structural design, performance features, application scenarios, technical specifications, and comparative advantages—helping you make a well-informed procurement decision.

The GC200 Jaw Crusher is a high-performance heavy-duty crusher developed by Leimeng, specifically engineered to meet high-capacity and high-intensity crushing requirements. The "C" in its name stands for "Crusher," while "200" refers to its impressive feed opening width of 2000mm, allowing it to process extremely large blocks of ore and rock materials with ease.

With its customizable configuration options, the GC200 can be tailored to meet specific operational needs, ensuring stable and efficient performance even in demanding conditions. Whether handling hard granite, basalt, or large volumes of iron ore or copper ore, the GC200 consistently delivers exceptional crushing performance.

Thanks to its outstanding technical specifications, the Leimeng GC200 Jaw Crusher sets itself apart in the market. Below is a detailed breakdown of its core parameters:

|

Parameter |

Specification |

|

Feed Length |

2000mm |

|

Feed Width |

1500mm |

|

Max Feed Size |

<1200mm |

|

Discharge Adjustment Range |

175–300mm |

|

Final Output Size |

≤450mm |

|

Capacity |

760–1590t/h |

|

Bearing Brand |

Top-tier Chinese brand |

|

Motor Power |

400KW |

|

Voltage |

380V |

|

Motor Speed |

990rpm |

|

Protection Level |

IP54 |

|

Insulation Class |

Class F |

|

Mounting Method |

B3 Type |

|

Frame Material |

Cast steel, welded steel plates |

|

Wear-resistant Material |

ZGMn13-4 manganese steel |

|

Drive Type |

Belt drive |

|

Lubrication System |

Grease lubrication |

|

Dimensions |

6575×3950×5040mm |

|

Weight |

139 tons |

These specifications reflect the jaw crusher and provide the high performance and efficiency needed in industries such as ore processing, construction waste recycling, and metal smelting. Moreover, the specifications can be tailored to meet specific operational conditions, offering exceptional customization flexibility.

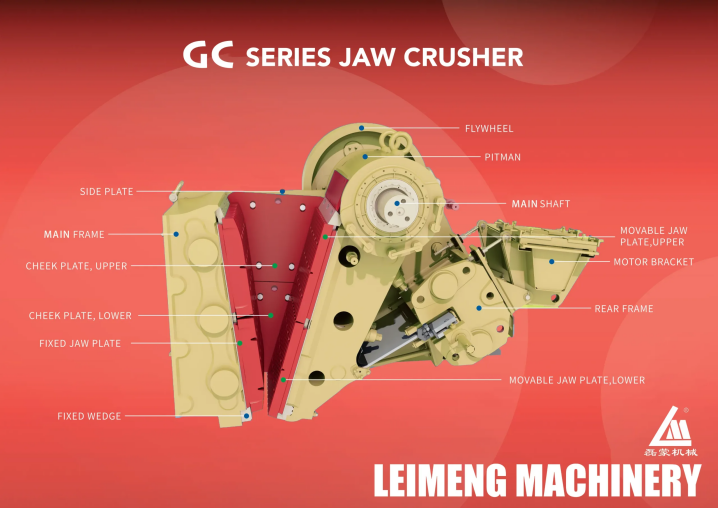

The GC200 jaw crusher demonstrates expert-level design in its structural configuration, tailored specifically for heavy-duty mining applications. Its components feature a modular, reinforced design, which enhances overall strength and ease of maintenance.

The frame is constructed using high-strength welded steel plates, treated to relieve internal stress. This design significantly reduces the risk of cracking or deformation caused by prolonged vibration during operation.

Both the movable and fixed jaw plates are made from high-manganese wear-resistant steel, with additional thickness to withstand hard materials like granite, basalt, and iron ore—commonly found in regions such as Russia.

The V-shaped crushing chamber and optimized bite angle ensure smooth material entry and more complete crushing. This not only enhances the particle shape of the final product but also reduces energy consumption and wear.

Equipped with large flywheels, the GC200 balances impact loads and maintains operational efficiency. The durable pulleys ensure consistent power output, even under extreme working conditions.

With its robust performance, the GC200 jaw crusher finds applications across numerous industrial sectors, demonstrating outstanding adaptability and efficiency in the following areas:

When compared to traditional jaw crushers, the GC200 offers significant benefits:

|

Comparison Metric |

GC200 Jaw Crusher |

Traditional Jaw Crusher |

|

Feed Capacity |

Up to 2000mm, handles large materials |

Typically <1200mm, limited feed |

|

Structural Integrity |

Integrated heavy-duty welded frame |

Assembled frame, prone to cracks |

|

Wear Part Longevity |

High-manganese custom materials |

Standard parts, frequent changes |

|

Smart Features |

Central lubrication & monitoring |

Manual oiling, no monitoring |

|

Energy Efficiency |

10%+ lower energy per ton output |

Higher operating costs |

The GC200 is more than just a high-efficiency crusher—it's a core driver of value for large-scale mining operations. Its stability, power, and smart features deliver unmatched performance, even under harsh conditions and continuous workloads.

If you're looking for a reliable, high-capacity jaw crusher that offers superior durability, intelligence, and customization, the GC200 is undoubtedly a smart choice. It meets the stringent requirements of modern mining and construction environments while optimizing operational costs.

Contact us today to learn more about the GC200 Jaw Crusher’s specifications, capabilities, and pricing, and discover how it can become the powerhouse of your production line—enhancing your competitive edge in the market.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent