Currency

A jaw crusher is one of the most versatile and widely used types of crushing equipment for primary crushing of hard and abrasive materials. These include various types of rocks, construction waste, recycled materials, metallic and non-metallic ores, and industrial by-products. This wide range of applications makes jaw crusher manufacturing a strategically important sector across many heavy industries.

The working principle of a jaw crusher is both simple and highly effective. Material is fed into the crushing chamber, where it is compressed between two jaws—one stationary and one moving in a reciprocating motion. This mechanical force breaks down the material into the desired size.

Modern jaw crushers are highly automated, feature ergonomic designs, and meet international standards for energy efficiency and environmental safety. Equipped with intelligent control systems, these machines allow real-time optimization of operating parameters, reduce energy consumption, extend the service life of wear parts, and improve overall productivity.

In recent years, there has been a consistent increase in demand for jaw crushers, prompting manufacturers in Europe, Asia, and North America to scale up production. They are incorporating digital solutions, advanced wear-resistant materials, and improved designs. Higher expectations for crushing quality, energy efficiency, and equipment reliability have made this market highly competitive and technologically advanced.

In a globalized and industrialized world, the leading manufacturers are those that not only supply products but also offer a full spectrum of engineering and support services—from designing complete crushing stations to supplying spare parts and technical support. These companies are shaping the future of the jaw crusher industry.

Here’s our expert ranking of the Top 10 global jaw crusher manufacturers in 2025, based on technological leadership, product innovation, build quality, and alignment with modern industrial demands.

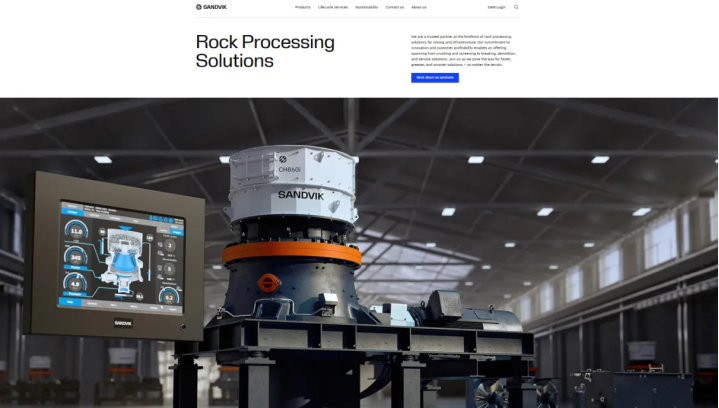

Flagship Model: CJ Series Jaw Crushers

Key Advantages:

Sandvik Mining and Rock Technology is a globally recognized leader in crushing equipment. Their CJ series jaw crushers are built for the toughest conditions, delivering long service life and stable output. Production complies with strict safety and energy efficiency standards.

Flagship Model: Nordberg® C Series

Key Advantages:

Metso Outotec offers some of the most trusted jaw crushers in the market. The Nordberg® C Series is known for its high crushing ratio and adaptability to project-specific conditions, setting a global benchmark in jaw crusher manufacturing.

Flagship Model: Powerscreen Series

Key Advantages:

Terex focuses on mobile solutions, especially useful in construction waste recycling. Their jaw crushers in the Powerscreen series are highly versatile and durable, designed for ease of use on project sites.

Flagship Model: MC Series

Key Advantages:

Part of the Wirtgen Group, Kleemann produces cutting-edge mobile jaw crushers. Their MC series combines German engineering with sustainable performance, making it a popular choice across Europe and Asia.

Flagship Model: BR Series

Key Advantages:

Komatsu uses advanced technologies to create mobile crushers tailored for construction sites and demolition work. The BR series performs well in space-restricted and unstable ground conditions.

Flagship Model: EB Series

Key Advantages:

Thyssenkrupp Industrial Solutions manufactures heavy-duty jaw crushers, suitable for mining and cement industries. The EB series excels in continuous production with minimal operational costs.

Flagship Model: FT Series

Key Advantages:

Popular in the Americas, Astec Industries offers jaw crushers known for their durability and adaptability. The FT series is designed to withstand harsh conditions and deliver consistent performance.

Flagship Model: J Series

Key Advantages:

McCloskey specializes in mobile crushing and screening plants, ideal for contractors. Their J series jaw crushers feature reinforced jaws and are fuel-efficient, making them a cost-effective solution.

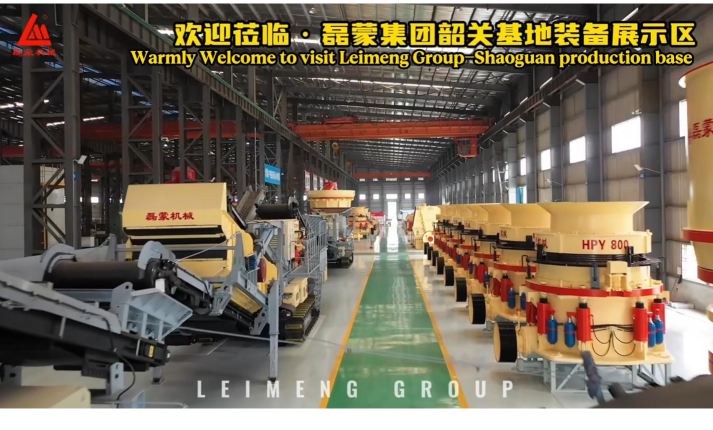

Flagship Models: PE Series, GC Series

Key Advantages:

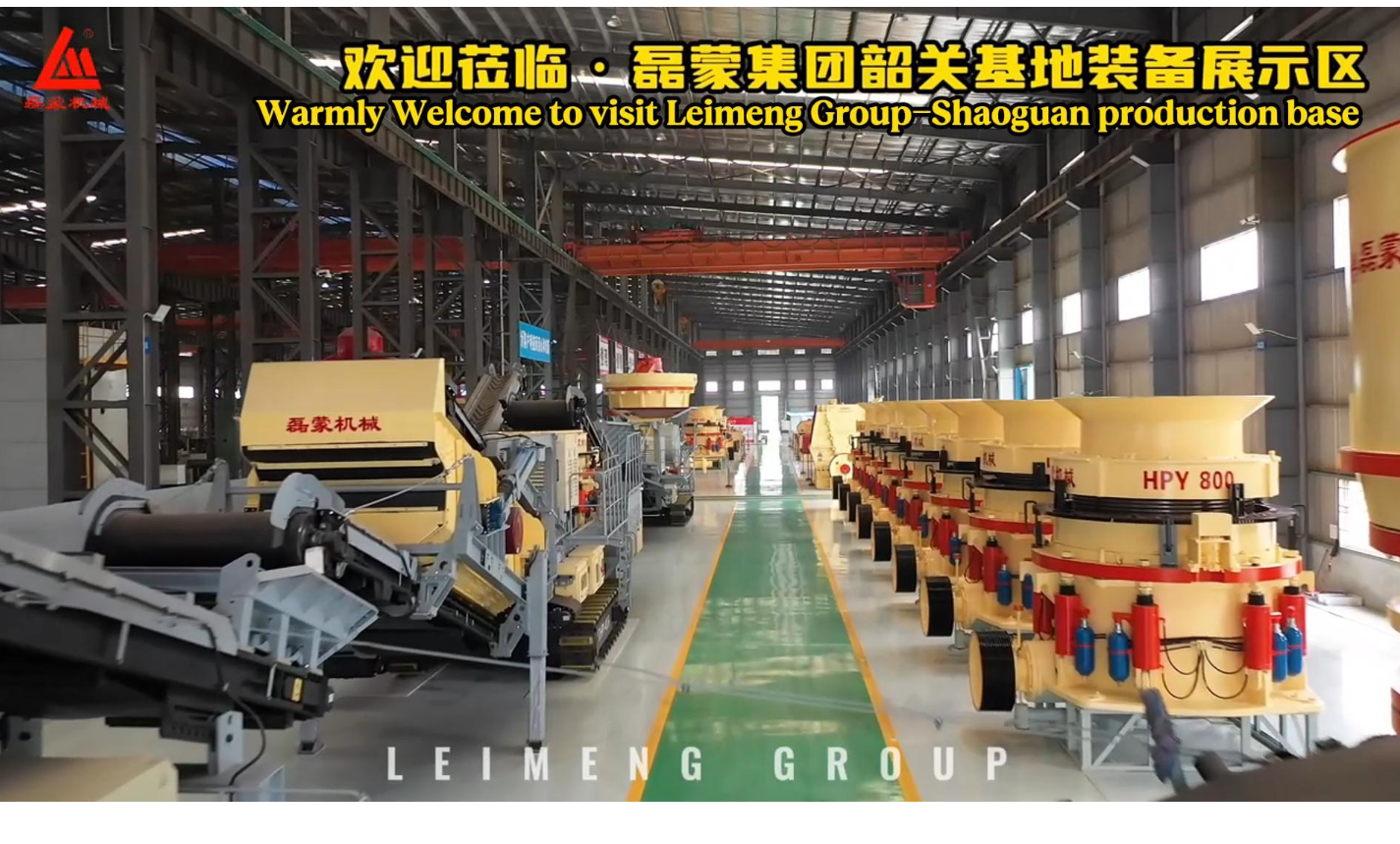

Guangdong Leimeng Intelligent Equipment Group Co.,Ltd. is built in 2009, specialized in R&D and manufacturing large-scale crushing and screening equipment, and providing integrated solutions for intelligent green mine.We hold more than 150 sets different types of processing equipment, mainly producing jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, mobile crushing station,vibrating screen and feeder, fine sand recycling machine, filter press, etc., and contracting the EPC project of sand and aggregate mine construction. The market share, brand awareness,quality status and other indicators of the products have reached the excellent level in the industry. In today's increasingly competitive and rapidly changing technology, in response to the call of the country, we continue to carry out research and development and iteration on the road to build energy-saving,environment-friendly and intelligent mining equipment.

LEIMENG Group has set up branches, offices and service centers in Vietnam, Indonesia, Russia, Kazakhstan, Tajikistan,Saudi Arabia ,Nigeria, Uganda, Congo, South Africa and other countries, We plan to build the next office in South American, Australia, Ethiopia,Malaysia and others countries LEIMENG Group's finished products and accessories are exported to more than 100 countries and regions.

Flagship Models: 3862, 4248

Key Advantages:

Lippmann builds professional-grade jaw crushers for mining companies. Designed for 24/7 operation in abrasive and extreme environments, their machines offer unmatched durability and output.

In 2025, the jaw crusher market continues to grow, driven by demand for reliable and energy-efficient equipment. Whether you need a mobile jaw crusher for a construction site or a heavy-duty stationary unit for a mining operation, the leading manufacturers listed above provide proven and innovative models that meet today's industrial needs.

When choosing a supplier, it’s crucial to evaluate not only the technical specifications but also the brand’s reputation, service availability, and certification compliance. The companies in our ranking represent the future of jaw crusher manufacturing.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent