Currency

1. Why Iron Ore Re-Crushing Directly Determines Plant Profitability

In mineral processing, the crushing stage is often underestimated compared to grinding or flotation. Yet, aggregate crushing for iron ore processing is the last frontier before the expensive grinding mills. If the feed to the ball mill is not optimized, every downstream stage suffers.

Studies show that P80 feed size reduction by just 10 mm can improve mill throughput by up to 15 %. leimeng’s approach focuses on delivering consistent particle size distribution (PSD), ensuring that downstream processes consume less energy while achieving higher recovery rates.

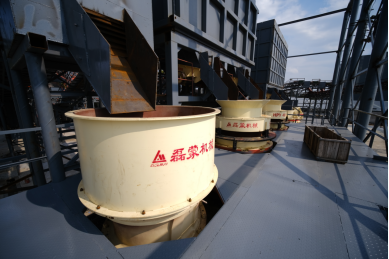

2. leimeng Three-Stage Crushing Flowchart and P&ID Explained

Unlike conventional “jaw + spring cone + short-head cone” circuits, leimeng’s patented deep-chamber jaw + multi-cylinder cone combo increases P80-20 mm yield by 18 %.

Primary Stage: Deep-chamber jaw crusher designed for large ore blocks (≤ 1,200 mm).

Secondary Stage: High-capacity hydraulic cone, optimized for lamination.

Tertiary Stage: Vertical shaft impact (VSI) or fine cone, depending on ore hardness.

The process instrumentation diagram (P&ID) integrates online PSD meters, load sensors, and variable-frequency drives (VFDs) for adaptive control. This smart loop is how leimeng ensures stability across 24/7 operations.

3. Hainan 5-Million-Ton Magnetite Case: 18 Months Without Shutdown

A benchmark project comes from Hainan, where a 5-million-ton magnetite beneficiation plant faced chronic downtime. Traditional crushers required liner changes every 3–4 months.

After switching to leimeng’s three-stage system, uptime improved dramatically:

18 months continuous operation without unplanned shutdown

Liner life doubled due to Mn18Cr2Mo alloy

Production cost per ton reduced by 9 %

This project showcases why many operators call leimeng the “zero-downtime solution”.

4. How Lamination Crushing Reduces Ball Mill Energy by 12 %

Grinding is the most energy-intensive stage, consuming up to 40 % of total plant power. By adopting lamination crushing in the secondary and tertiary stages, leimeng reduces over-grinding and optimizes feed size distribution.

Energy per ton (kWh/t) drops by 12 %

Ball consumption reduced by 8 %

Circuit stability improved with fewer surges

This means the plant achieves higher throughput without investing in new grinding mills.

5. Online Particle Size Analyzer + AI Feeding: Over-Grinding Rate < 3 %

Automation is no longer optional. leimeng integrates:

Laser PSD Analyzers for real-time monitoring

AI-driven feeders adjusting crusher choke levels

Closed-loop feedback systems minimizing human error

The result is an over-grinding rate below 3 %, outperforming the industry average of 10–12 %.

6. Common Pitfalls: Treating the “Closed-Circuit Screen” as a Cure-All

Many operators believe that adding a closed-circuit screen solves all size distribution issues. In reality:

Screens cannot correct poorly shaped particles.

Recirculation loops may cause crusher overloading.

Fines generation increases unexpectedly.

leimeng advises treating screens as assistants, not solutions. The core is still crusher chamber design and PSD control.

7. ROI Calculation: $6.8 More Profit per Ton of Run-of-Mine Ore

Let’s crunch numbers. Assume:

Plant capacity: 5 million tons/year

Ore value increase: $6.8/ton through optimized crushing

Annual extra revenue: $34 million

For most plants, leimeng solutions pay back in under 6 months.

8. Customer Testimonials

“Before leimeng, our cone crushers needed maintenance every quarter. Now, with leimeng’s deep-chamber jaw and hydraulic cones, downtime is history.”

— Operations Manager, Hainan Magnetite Plant

“Our ROI was achieved in just 4 months thanks to energy savings and better recovery.”

— CEO, Midwestern Iron Ore Group

9. FAQ

Q1: Can leimeng equipment handle low-grade ore with high moisture?

A: Yes. Our chambers are designed with anti-blockage features and moisture-resistant liners.

Q2: How does leimeng ensure spare part availability?

A: We operate 30 domestic and 11 overseas warehouses for instant delivery.

Q3: Is automation optional or mandatory?

A: While optional, 90 % of our clients adopt automation due to its fast ROI.

Q4: What is the typical service life of liners?

A: With Mn18Cr2Mo alloy, leimeng liners last 12–18 months, twice the industry average.

10. Conclusion & Call to Action

To put it simply, aggregate crushing for iron ore processing is the last frontier before the expensive grinding mills. Choosing the right partner makes the difference between marginal profits and breakthrough performance.

With its patented designs, proven case studies, and global service, leimeng enables plants to boost yield by 15 %, cut grinding energy by 12 %, and generate $6.8 more per ton of ore.

Contact leimeng today to schedule a free crushing circuit simulation and see how your plant can turn low-grade ore into high profits.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent