Currency

As global construction and infrastructure projects continue to expand, manufactured sand is playing an increasingly vital role as a replacement for natural sand. In sectors such as concrete production, highway and bridge construction, airport projects, and real estate development, high-quality manufactured sand is essential to ensure engineering quality.

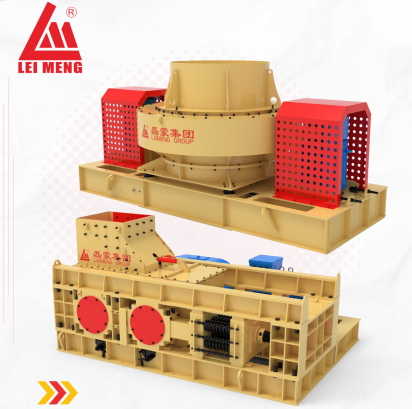

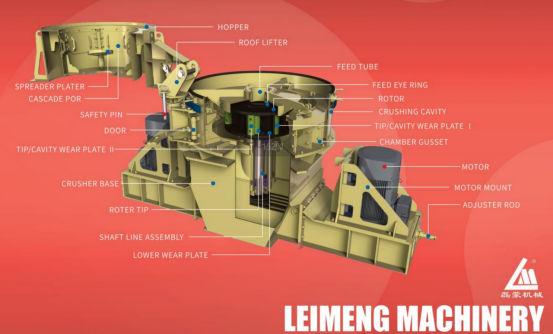

At the heart of manufactured sand production is the sand making machine, a core component of the process. Currently, two major types of sand making machines dominate the market: the VSI Vertical Shaft Impact Crusher and the 2PG Series Double Roller Crusher.

As a leading Chinese sand making machine manufacturer, Leimeng has developed mature technologies and amassed numerous successful project cases involving both types of equipment. We are capable of providing efficient, energy-saving, and customized sand production line solutions for clients in regions such as the Middle East, Africa, and South America.

Key Features:

The 2PG series double roller crusher operates on a principle of compression and shearing between two rollers. Under the combined pressure of hydraulic cylinders and springs, material is crushed as it passes between the rollers.

Key Features:

|

Aspect |

VSI Impact Crusher |

2PG Double Roller Crusher |

|

Grain Shape |

Materials are crushed into mostly cubic particles with less than 10% flakiness. Excellent particle shape meets high-grade aggregate standards. |

The grain shape is relatively rounded and close in quality to VSI output. Leimeng's national-level laboratory confirms compliance with Chinese manufactured sand standards. |

|

Finished Product Rate |

Typically 30%–40%. Due to impact crushing, over-crushing leads to more fines and lowers the effective yield. |

Much higher at 65%–80%. Compression-shearing mechanism reduces over-crushing, improving effective yield. |

In real-world applications, Leimeng’s 2PG roller crusher demonstrates a clear advantage in finished product yield and particle control, making it especially suitable for large-scale production and energy-conscious projects.

The VSI impact crusher has an energy consumption of 2.8–3.5 kWh per ton. Due to its high-speed rotating rotor, it requires significant power input, resulting in relatively high energy consumption. Additionally, energy losses occur during crushing, such as dissipation from high-speed impact and over-crushing of materials, leading to lower energy efficiency.

The 2PG double-roll crusher consumes only 1.7–2.1 kWh per ton, saving 40% in electricity compared to the VSI impact crusher, with significantly improved energy efficiency.

For example, at the same processing capacity of 400 tons per hour:

Its low-speed operation (roll speed <15 m/s) reduces energy loss and avoids the energy dissipation caused by high-speed impact, enhancing overall energy utilization.

Additionally, the utilization rate of the roller liner is as high as 88%. The machine adopts solid rollers with solid liners, extending liner life to 800–1200 hours, significantly improving durability.

Ideal for:

Ideal for:

Leimeng provides complete sand production solutions, including coarse crushing, secondary crushing, sand making, screening, washing, and dust removal—all tailored to various terrains and project requirements.

If your project prioritizes superior grain shape and fine sand precision, consider:

→ Leimeng VSI Sand Making Machine

If your project emphasizes high output rate, low energy consumption, and low operating costs, we recommend:

→ Leimeng 2PG Double Roller Crusher

With rich experience in international projects, Leimeng has delivered customized sand production lines to clients across the Middle East, Africa, South America, and Southeast Asia—helping them achieve higher productivity, lower energy use, and stronger market competitiveness.

Feel Free to Contact Us

🌐 Website: www.lmcrusher.com

📞 Tel/WhatsApp/WeChat: +86 18922482175

📧 Email: sarah@crusherlm.com

🏢 Address: No. 152 Xingye Road, Longxing Village, Aotou Town, Conghua District, Guangzhou, China

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent