1. Introduction: The Role of Cone Crushers in Mining Operations

Cone crushers play a vital role in secondary and fine crushing processes, significantly impacting production line efficiency and finished product shape. Selecting the right cone crusher directly influences output capacity, operating costs, and return on investment.

To help customers make informed decisions, this article compares several mainstream cone crusher models available on the market, including those developed by Leimeng, analyzing their performance, efficiency, and suitability for different applications.

2. Overview and Feature Comparison of Key Models

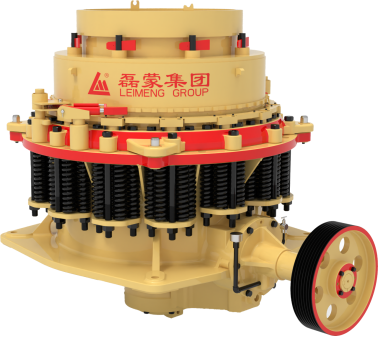

PYB Spring Cone Crusher (Traditional Type)

- Simple structure and cost-effective, supported by Leimeng’s mature manufacturing process

- Low automation, limited particle shape control

- Suitable for small to medium-sized sand and gravel production lines

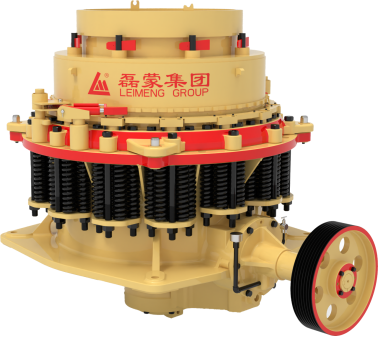

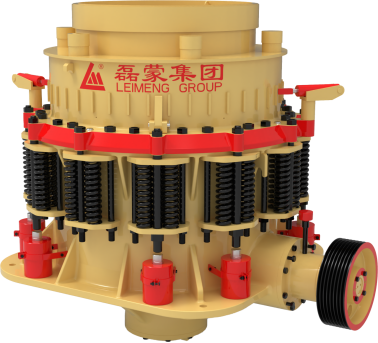

S Series Cone Crusher (Symons-Type Structure)

- Multiple crushing chamber options: Offers three different chamber designs to suit site conditions, delivering high efficiency, uniform particle size, and reduced liner wear.

- Grease-sealed dust prevention: Unique sealing structure prolongs lubricant life and reduces part wear.

- Supports higher crushing force: Key parts made of special materials; longer stroke allows more material intake and higher throughput.

- Higher output: Longer crushing arm and stroke enable more efficient crushing per cycle.

- Low maintenance costs: Thoughtful structural design reduces load on bearings and gears, with hydraulic clearing system minimizing downtime.

- Advantages over PYB: Uses a pulley instead of coupling, grease sealing instead of water sealing, added hydraulic lifting device, and improved chamber shapes with coarse/medium/fine options.

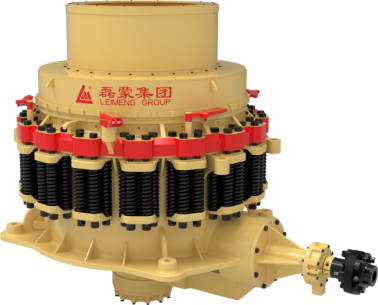

LMC Series (Leimeng Multi-Cylinder Hydraulic Cone Crusher)

- Hydraulic adjustment + hydraulic clearing for easy operation

- Large crushing ratio and high output

- Suitable for high-performance projects requiring superior productivity

- Simple structure and high reliability: One hydraulic cylinder, compact design, low failure rate, and low production cost

- Dynamic discharge adjustment reduces downtime and improves efficiency

- High output: Steep cone angle accelerates material flow for better throughput

- Constant Liner Performance (CLP) design ensures stable capacity throughout liner wear cycle

- Floating main shaft with dual-end support offers strong load-bearing capability

- Spiral bevel gear transmission: High strength, smooth operation, and low noise (also available in HPY series)

- Heavy-duty design ensures durability under harsh working conditions

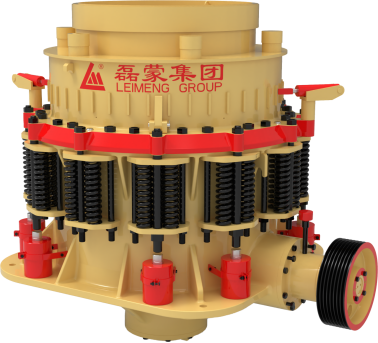

HPY Series (Leimeng Intelligent Cone Crusher)

High energy crushing + remote monitoring, ideal for smart mining operations.

Adopts laminated crushing, producing cubic-shaped finished products with minimal over-crushing.

- High crushing ratio & productivity: Large cone angle, big eccentricity, and high-speed operation greatly enhance rated power and throughput

- Wear resistance with high-manganese steel & material bed protection: Reduces wear part consumption and operating costs

- Advanced sealing: Combination of positive pressure dust protection and non-contact labyrinth seal effectively protects lubrication and bearings

- Easy maintenance: All parts can be disassembled from the top or side, simplifying regular maintenance

- Centralized thin oil lubrication system: Provides multi-point timely lubrication, reducing friction, wear, and energy loss while extending service life

- Flexible chamber types: Replace liners to switch between standard coarse and short-head fine chambers, easily adapting to different product sizes

3. Comparison

Evaluating by control system, particle shape, cost, automation level, and application:

|

Model Type

|

Recommended Application

|

|

PYB Spring Cone Crusher

|

Small to medium-sized aggregate lines

|

|

S Series Spring Cone Crusher

|

Secondary crushing

|

|

LMC Compound Cone Crusher (Leimeng)

|

Mid to high-end crushing projects

|

|

DS/DH Single-Cylinder Cone Crusher

|

High capacity, stable performance, suitable for secondary/tertiary crushing of hard ores

|

|

HPY Multi-Cylinder Cone Crusher (Leimeng)

|

Smart mining and large-scale projects

|

4. How to Choose the Right Cone Crusher (Selection Tips)

Selection should be based on raw material type, discharge requirements, and desired capacity scale:

- For new projects with limited budget → S Series

- For high capacity and intelligent automation needs → LMC, DS, or HPY Series

Leimeng offers one-stop solution design, trial testing with demo machines, and on-site technical support.

5. Conclusion

There is no absolute “best” cone crusher—only the most suitable crushing solution for your needs.

Contact Leimeng for personalized equipment selection advice. We serve clients across the globe, helping them build successful crushing plants from the ground up.

Feel Free to Contact Us

🌐 Website: www.lmcrusher.com

📞 Tel/WhatsApp/WeChat: +86 18922482175

📧 Email: sarah@crusherlm.com

🏢 Address: No. 152 Xingye Road, Longxing Village, Aotou Town, Conghua District, Guangzhou, China