Currency

Cone crushers are core equipment in production lines for mining, aggregates, and manufactured sand.

The Leimeng S Series Cone Crusher has gained strong recognition in overseas markets for its stable performance, excellent particle shape, and outstanding cost-effectiveness.

This article presents a systematic analysis of its working principle, structural features, application advantages, and global adaptability.

Recommended keywords: S series cone crusher, cone crusher for sale, stone crusher Africa, cone crusher South America, crushing equipment Middle East

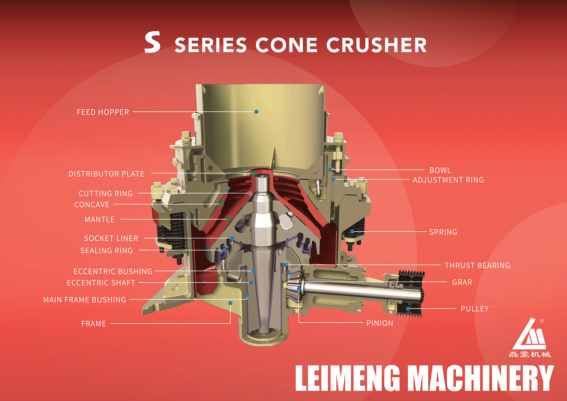

The motor drives the eccentric sleeve to rotate via a triangular belt, large pulley, transmission shaft, bevel gears, and large cone gear. The eccentric shaft nested in the sleeve undergoes a gyratory motion, mainly revolving.

The moving cone installed on the main shaft oscillates and approaches or leaves the concave (fixed cone), repeatedly crushing the material in the annular crushing chamber through compression, impact, and bending.

After multiple actions, the material is broken down to the desired particle size and discharged from the bottom outlet.

The S Series Cone Crusher consists of: frame, moving cone, fixed cone, main shaft, eccentric sleeve, adjustment system, electrical system, thin oil lubrication system, and hydraulic clearing system.

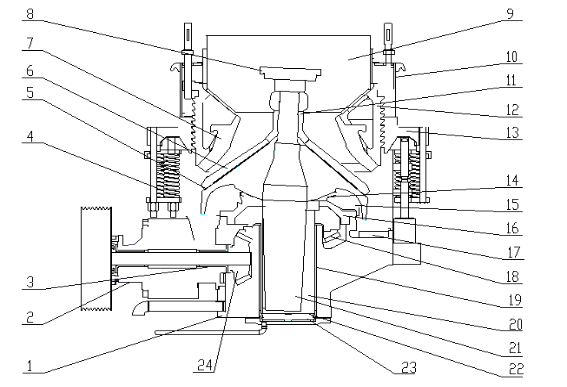

|

No. |

Part Name |

No. |

Part Name |

|

1 |

Frame |

13 |

Support sleeve |

|

2 |

Shaft bracket |

14 |

Bowl-shaped bearing seat |

|

3 |

Shaft sleeve |

15 |

Bowl bracket seal ring |

|

4 |

Spring (short/long) |

16 |

Bowl bracket |

|

5 |

Body |

17 |

Reinforced guard plate |

|

6 |

Crushing wall |

18 |

Small bevel gear |

|

7 |

Concave wall |

19 |

Frame liner |

|

8 |

Distributor plate |

20 |

Eccentric sleeve |

|

9 |

Hopper |

21 |

Main shaft bushing |

|

10 |

Adjustment cap |

22 |

Upper thrust plate |

|

11 |

Cut ring |

23 |

Lower thrust plate |

|

12 |

Adjustment sleeve |

24 |

Large bevel gear |

Standard Type (left diagram):

Short Head Type (right diagram):

Both types can be subdivided into coarse, medium, and fine cavity configurations for precise gradation control.

Multiple Crushing Chamber Designs: The S Series Cone Crusher offers three different chamber designs, allowing users to choose the most suitable one based on site-specific material characteristics and production goals. These options enable higher crushing efficiency, more uniform product particle size, improved particle shape, and even wear of the concave liner (mantle), which extends service life and reduces replacement frequency.

Reliable Grease-Sealed Dust Prevention: The S Series adopts a unique dry oil sealing structure for dust prevention. This system provides a reliable seal, effectively preventing dust intrusion into the lubrication system. As a result, the lubrication oil replacement cycle is extended, and the wear life of internal components is significantly prolonged.

Supports High Crushing Force: Key components of the S Series Cone Crusher are made from special high-strength materials, enhancing its capacity to handle high crushing forces. During each stroke, the moving cone travels a large distance away from the concave wall, allowing a greater volume of material to enter the crushing cavity and enabling a larger discharge volume. This design increases throughput speed and improves processing efficiency.

High Productivity: Compared to other cone crusher models, the S Series features a longer crushing arm, extended stroke, and greater crushing force, allowing it to crush more material during each stroke. This results in significantly higher output, particularly beneficial for operations requiring large-scale production.

Low Maintenance Cost in Daily Operation: Reasonable material selection and structural design of parts, long service life, long crushing arm, reduced load on sliding bearings, gears and frames, uniform particle size of crushed products, reduced circulating load, easy operation of hydraulic cavity cleaning system, reduced downtime, low power consumption and reasonable distribution.

Lower automation level, not ideal for intelligent mining operations

Particle shape is less refined than that of multi-cylinder hydraulic models

Discharge port adjustment requires manual operation and equipment downtime

Ideal for traditional mining operations with mature workflows and budget control needs

The Leimeng S Series is widely used in:

Affordable pricing with low maintenance cost

No need for highly specialized technicians — easy to maintain and repair

OEM customization support (feed/discharge sizes, voltage standards)

Leimeng offers multiple overseas installation cases and agent support networks

Choose model based on:

Leimeng supports customized configurations, export packaging, and on-site installation guidance.

The S Series Cone Crusher is your reliable partner for efficient crushing.

Leimeng provides turnkey crushing solutions for customers across various global markets.

Contact us for model recommendations, demo testing, and quotation requests.

Join clients worldwide—choose Leimeng for affordable, reliable, and high-performance crushing equipment.

Feel Free to Contact Us

🌐 Website: www.lmcrusher.com

📞 Tel/WhatsApp/WeChat: +86 18922482175

📧 Email: sarah@crusherlm.com

🏢 Address: No. 152 Xingye Road, Longxing Village, Aotou Town, Conghua District, Guangzhou, China

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent