Currency

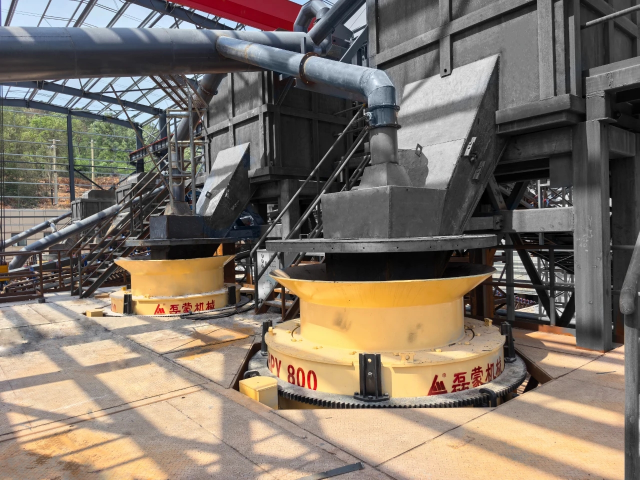

In the mining industry, cone crushers play a vital role in the coarse, medium, and fine crushing of ores. Whether it involves metallic or non-metallic ore extracted from quarries or underground mines, the raw materials are typically too large to be directly processed or enriched. Cone crushers are designed to break down these oversized rocks into more manageable sizes, creating optimal conditions for subsequent processes like grinding and flotation.

For instance, in copper mining, a cone crusher can reduce the size of copper ore for initial processing, making it suitable for the milling stage. This not only improves the efficiency of the beneficiation process but also enhances resource utilization. Additionally, in the mining of rare metals, the high-precision crushing provided by cone crushers helps to increase ore recovery rates and minimize resource loss.

Cone crushers also serve a critical function in the construction sector. The production of building materials demands a large quantity of crushed aggregates. Cone crushers efficiently process various rocks and ores into crushed stone of different sizes, meeting the required standards for construction aggregates.

For example, high-quality gravel is essential for the base and top layers of road surfaces. Aggregates produced by cone crushers feature uniform grain sizes and good particle shapes, which improve road durability and load-bearing capacity. In high-rise construction, where concrete aggregates must meet stringent standards, cone crushers provide well-graded, high-strength materials, ensuring structural safety and stability.

The application of cone crushers is indispensable for the advancement of the mining and construction industries. These machines not only improve production efficiency and reduce costs but also guarantee stable and high-quality output. The proper selection and use of cone crushers can help enterprises optimize resource utilization, reduce energy consumption, and achieve sustainable development.

In the following sections, we’ll explore the working principle of cone crushers, their key features, and the operational advantages they offer, helping users better understand and utilize this essential equipment.

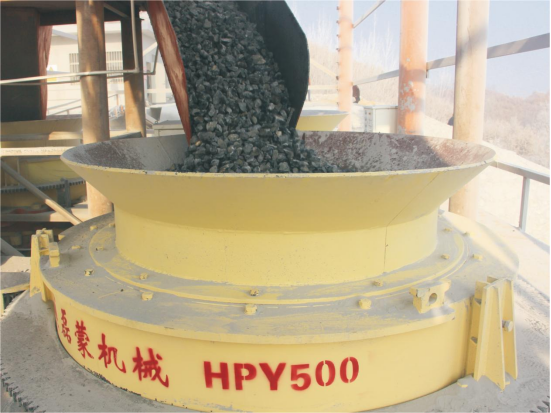

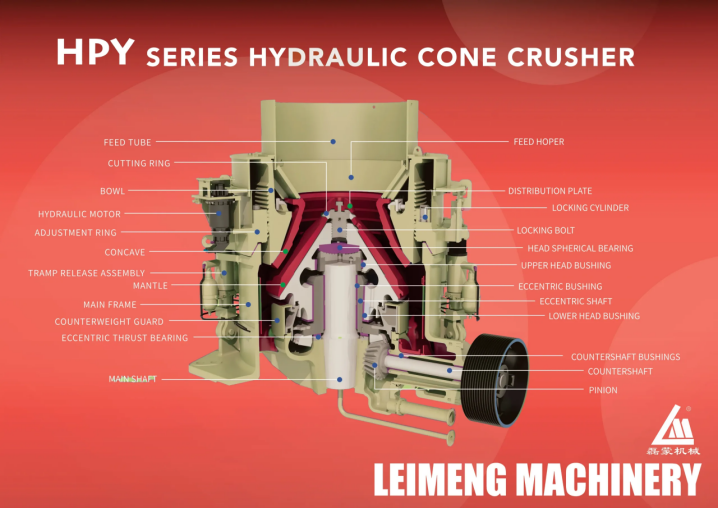

Cone crushers primarily utilize compressive force to break down materials. The key components include a moving crushing cone, a stationary crushing cone, and a power transmission system driven by an electric motor.

The structure of a typical cone crusher comprises a frame, transmission system, eccentric housing, bowl bearing, crushing cone, adjustment device, adjustment sleeve, springs, and discharge opening. The electric motor drives the eccentric shaft, causing the moving crushing cone to oscillate. This movement enables the compression and fragmentation of materials inside the crushing chamber.

As the eccentric shaft rotates, the moving cone moves toward and away from the stationary cone. When the two cones are close, the material between them is crushed under compressive, bending, and shearing forces. The material continues to break down and move downward through the chamber until it is discharged through the bottom opening.

The gap between the crushing cones can be adjusted, which is key to controlling the final particle size. By altering this gap, operators can control the retention time and crushing force applied to the material. For finer products, the gap is reduced; for coarser products, it is widened.

Cone crushers deliver a high reduction ratio, allowing large chunks of material to be efficiently reduced in a single pass. This minimizes the number of crushing stages required, simplifying the production process and improving throughput.

Moreover, cone crushers offer excellent control over product shape. Thanks to optimized chamber design and adjustable parameters, the output features uniform, cubic-shaped particles with minimal needle-like or flaky content. Such characteristics are highly desirable in construction applications like concrete production, where they improve workability and strength.

In an era of increasing energy scarcity, energy efficiency is crucial. Cone crushers are engineered with energy-saving features, including optimized drive systems, improved chamber geometry, and advanced crushing technology.

Modern electric motors and transmission units enhance power delivery, while chamber optimizations ensure effective material contact, reducing energy loss. Compared to traditional crushers, cone crushers can achieve the same output while consuming less power—lowering overall production costs.

Operating under high-impact and abrasive conditions, cone crushers are built using wear-resistant, high-strength materials for key components like liners and crushing surfaces. These materials withstand harsh working conditions and significantly extend the equipment’s service life.

Precision manufacturing and tightly fitted components ensure the machine operates reliably over time, minimizing breakdowns and maximizing uptime.

Cone crushers are user-friendly and straightforward to operate. After basic training, operators can quickly learn how to use the machine effectively. Many models feature advanced automation systems, allowing remote monitoring and control, improving both safety and convenience.

Adjusting product size is quick and easy, either by modifying the chamber gap or changing liner specifications. This flexibility enables rapid adaptation to different production requirements.

One of the standout benefits of cone crushers is their versatility. They are suitable for a wide range of materials, from hard rocks like granite and basalt to medium-hard stones like limestone and sandstone.

With adjustable settings, a cone crusher can handle coarse, medium, and fine crushing tasks, making it ideal for mining, construction, and other industrial applications.

Our cone crushers feature a well-organized interface, with intuitive button placements and indicator lights that simplify machine operation. The equipment is designed for easy assembly and disassembly, streamlining maintenance and repairs.

To reduce operational complexity, our machines are equipped with smart adjustment systems. These automatically modify critical parameters like chamber gap and eccentric speed based on material properties, desired particle size, and production goals.

Operators only need to input target values, and the system will manage the rest. In addition, automatic fault detection and alert systems enhance operational safety and reduce downtime.

We design our cone crushers with cost-efficiency in mind. Advanced manufacturing techniques and premium components improve equipment reliability and lifespan, lowering the frequency of repairs.

The machine’s modular construction allows for easy parts replacement and routine maintenance. Our robust after-sales service and spare parts supply ensure smooth and uninterrupted operation for our clients.

As a key component in mining and construction, the cone crusher offers unmatched value through its innovative design, high efficiency, and reliability. Its powerful crushing capability, precision in particle shaping, energy-saving performance, long-term stability, user-friendliness, and versatility make it an essential tool in modern industry.

Our cone crushers provide clear operational advantages, including intuitive interfaces, smart adjustment systems, and minimized maintenance costs. As technology continues to advance, cone crushers will evolve further, contributing even more to the sustainable development of mining and construction industries.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent