Currency

As the global mining industry evolves toward greater scale, automation, and intelligence, mining companies are increasingly focused on improving productivity, reducing operating costs, and enhancing equipment reliability. In response to these demands, multi-cylinder hydraulic cone crushers are gaining popularity. Thanks to their high level of automation, excellent finished product shape, superior output, and large crushing ratio, they have become the preferred equipment for medium and large-scale crushing across sectors such as mining, construction materials, cement, and chemicals.

Among the many models of hydraulic cone crushers, the MPY1250 stands out as a true giant in the industry. With its remarkable power, intelligent hydraulic control system, and exceptional performance, this crusher sets a new industry standard in high-performance crushing equipment. In this article, we explore the MPY1250 hydraulic cone crusher from technical, structural, and operational perspectives, covering key specifications, core components, control systems, and investment returns.

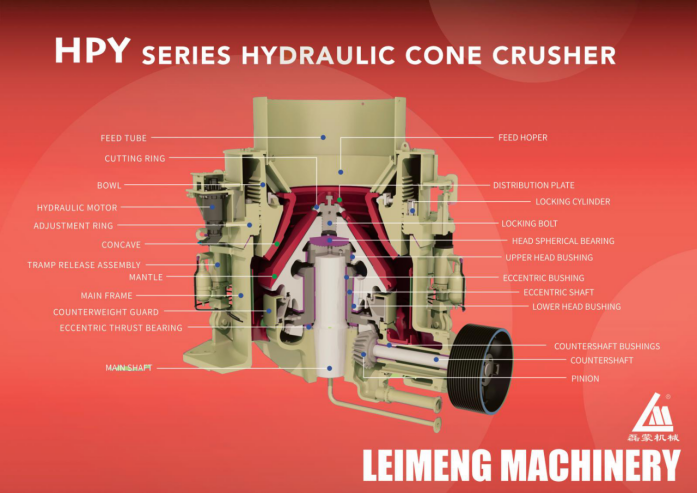

A cone crusher crushes material through a combination of compression and impact. The device features a moving and a stationary cone that form a crushing chamber. As the eccentric shaft drives the moving cone to rotate, it creates a variable annular space between the two cones. When ore enters the chamber, it is compressed, bent, and sheared between the cones, enabling it to be crushed to the desired particle size.

Compared to jaw crushers, cone crushers provide better final product shape, higher throughput, and enhanced automation—especially in hydraulic models, which allow precise control over discharge settings and fast chamber clearing during blockages, significantly improving reliability and ease of maintenance.

A multi-cylinder hydraulic cone crusher—such as the MPY1250—is defined by its multiple hydraulic cylinders operating in synchronization. Unlike single-cylinder models, the MPY1250 uses several cylinders, each performing distinct tasks including main shaft support, chamber clearing, and overload protection.

During operation, the synchronized hydraulic system ensures even load distribution on the moving cone and adjusts the discharge opening in real time based on ore hardness. This guarantees stable crushing efficiency under varying load conditions. Additionally, the automatic chamber-clearing function minimizes downtime by instantly relieving pressure when foreign objects or hard inclusions enter the crushing zone.

The hydraulic system of the MPY1250 is controlled via a PLC controller, which continuously monitors machine load and automatically adjusts the discharge setting based on pressure feedback, enabling intelligent discharge control. This not only stabilizes the crushing process but also reduces the need for manual intervention.

| Model | Power (kW) | Capacity (t/h) | Length (mm) | Width (mm) | Height1 (mm) | Height2 (mm) |

| MPY1000 | 800 | 615–2420 | 4805 | 3900 | 3870 | 4540 |

| MPY1250 | 900 | 590–3025 | 5000 | 4700 | 5050 | 5790 |

| Model | Capacity Range (t/h) | Max. Feed Size (mm) | Discharge Opening (mm) | Power (kW) | Dimensions (mm) |

| MPY1250 | 590–3025 | 900 | 360 | 900 | 5000 × 4700 × 5050 × 5790 |

| MPY1000 | 615–2420 | 800 | 360 | 800 | 4805 × 3900 × 3870 × 4540 |

| HPY900 | 341–1440 | 700 | 356 | 700 | — |

| Final Product Size (mm) | HPY900 | MPY1000 | MPY1250 |

| 10mm | — | — | 590–700 |

| 13mm | 341–568 | 615–730 | 770–915 |

| 16mm | — | — | 835–1020 |

| 19mm | 457–600 | 720–900 | 900–1125 |

| 25mm | 545–876 | 915–1210 | 1145–1510 |

| 32mm | — | — | 1455–1510 |

| 38mm | 660–1140 | 1375–1750 | 1720–2190 |

| 44mm | — | — | 2000–2610 |

| 50mm | 864–1440 | 1830–2420 | 2290–3025 |

From the above data, the MPY1250 features a feed opening that is 100 mm larger than standard models with an 800 mm intake, and its power is 100 kW higher. This results in 25% greater output, allowing the crusher to process larger ore chunks per pass and improve overall production efficiency and continuity.

The MPY1250 is not only technically advanced but also field-proven in demanding mining environments across.

For instance, in a copper ore crushing project, the MPY1250 processes material up to 900 mm in size in a single pass and handles hard ores with ease. Daily output exceeds 2800 tons, and the equipment operates 24/7 with minimal downtime, providing substantial gains in operational efficiency and reduced maintenance costs.

In Siberia, the MPY1250 is widely used in the production of aggregates from frozen and permafrost rocks. The crusher delivers a uniform output with over 85% cubical shape, meeting stringent requirements for road base materials. These high-quality aggregates are directly used in road construction, offering significant economic value.

The MPY1250 is also highly effective in recycling secondary materials, such as concrete and blast furnace slag. With its adjustable discharge settings, it can produce materials ranging from 5 to 40 mm, tailored to specific production requirements. This aligns with the goals of green mining and supports circular economy initiatives by enabling sustainable resource utilization.

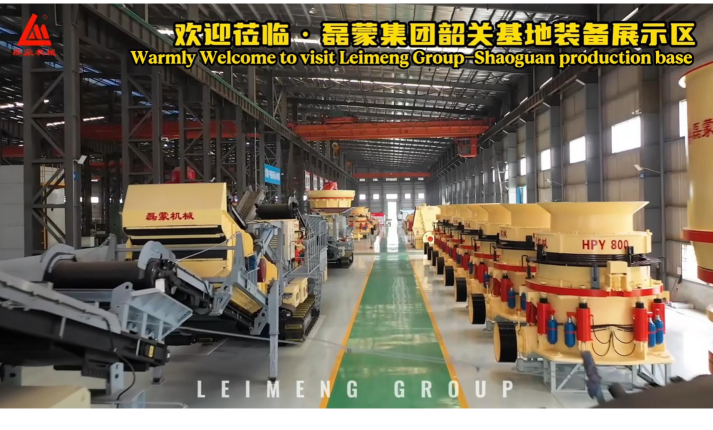

Leimeng is a leading manufacturer of crushing equipment with over 30 years of R&D experience. From the HPY900 to the flagship MPY1250, the company continuously innovates to meet global industry standards. Leimeng equipment is certified with CE, ISO9001, making it widely trusted in the international market.

As the largest multi-cylinder hydraulic cone crusher in the world, the MPY1250 excels in performance, design, and intelligent control. It empowers mining enterprises to significantly boost productivity, cut operational costs, and maximize return on investment.

By choosing the MPY1250, you're investing in efficiency, intelligence, safety, and sustainability—everything modern mining operations demand from their crushing equipment.

1. Why is hydraulic protection preferred over spring systems?

Hydraulic systems respond faster, allow precise force control, and enable chamber clearing without shutdown. Spring systems rely on mechanical tension, are less flexible, and wear out faster.

2. How is a multi-cylinder crusher better than a single-cylinder crusher?

Multi-cylinder models offer better load distribution, synchronized adjustments, and higher reliability. They allow precise discharge control and efficient chamber clearing, leading to better overall performance and automation.

3. What is the benefit of a 900 mm feed opening?

A large feed size reduces the need for primary crushing, simplifying the crushing process, cutting equipment costs, and increasing crushing efficiency.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent