Currency

In mining, construction waste recycling, cement production, and highway construction, project teams often face tight deadlines, complex sites, and frequent equipment relocations. Although traditional fixed crushing equipment offers high capacity, its long deployment cycle, high relocation costs, and limited site adaptability hinder project flexibility.

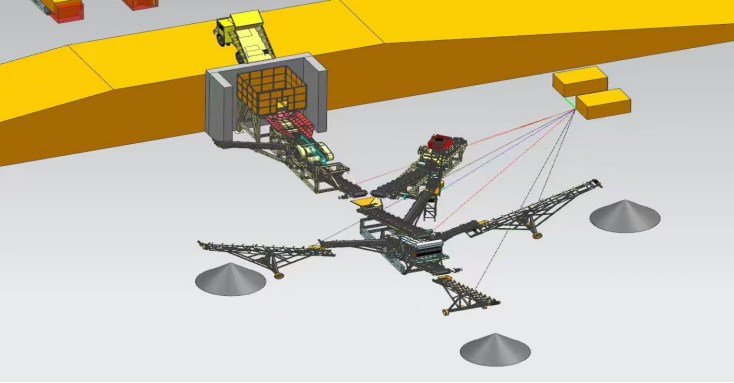

A skid-mounted crusher Supplier integrates crushing equipment (jaw crusher, cone crusher, impact crusher, etc.) onto a steel skid base platform with a modular design. It requires no complex concrete foundations and is delivered as a complete assembled unit. This design significantly reduces setup time and labor costs, making it ideal for temporary projects and multi-site operations.

Foundation-free installation

Modular integrated design

Rapid transportation and relocation

Reduced construction and labor costs

Construction Companies with Multiple Sites and Frequent Equipment Moves

Achieve flexible deployment with “one skid, multiple uses,” reducing repeated capital investment.

Remote and Challenging Terrain Projects

Skid-mounted crushers adapt well to highland, mountainous, or remote sites where transportation is difficult.

Temporary or Emergency Repair Projects

Ideal for emergency disaster relief, quick road repairs, or temporary mining sites where rapid installation within 24–48 hours is required.

High-Strength Skid Base

Constructed with welded H-beams or channel steel for robust stability, suitable for lifting and transportation.

Integrated Modular Layout

Crushing unit, electrical control cabinet, feeder, conveyor belt, and dust removal systems are combined, minimizing on-site wiring and civil works.

Easy Installation

No civil foundation needed; only simple padding and positioning devices are required for operation.

Convenient Transportation

Designed to fit semi-trailers or containers for efficient cross-regional relocation.

Choosing a reliable supplier ensures efficient operation and solid after-sales support. Focus on:

1. Custom Engineering Capability

Optimize skid system layout based on material type and capacity.

Provide turnkey solutions, including crushing, screening, and dust control.

Offer CAD/3D modeling and detailed construction drawings.

2. Electrical Control and Auxiliary Equipment Integration

Equip with branded PLC intelligent control systems for remote monitoring and start-up.

Select feeders, conveyors, and screening equipment matched to crusher performance.

Provide standardized wiring diagrams, manuals, and fault diagnosis tools.

3. Overseas Project Experience and Certification

Comprehensive shipping, anti-corrosion treatment, and export documentation.

International certifications such as CE and UL.

English installation guides and remote commissioning support.

Overseas agents and quick spare parts supply network.

Project A: Remote guidance helped complete assembly and testing within two days, achieving stable output. The customer subsequently ordered two additional units for African markets.

Project B: A mining group successfully rotated skid-mounted crushers across multiple sites, lowering capital expenditure and downtime.

Save Time: Deployment time reduced by over 70% compared to traditional fixed equipment.

Reduce Investment Risk: Equipment reuse across projects lowers repeat purchases.

Enhance Flexibility: Adaptable to complex terrain and temporary needs.

Simplify Maintenance: Modular design eases repair and component replacement.

As a flexible and efficient modular crushing solution, skid-mounted crushers lead the smart, convenient upgrade of equipment in mining and construction industries. Selecting an experienced, technology-leading skid-mounted crusher supplier is crucial for project success and long-term profitability.

🌐 Website: www.lmcrusher.com

📞 Tel: +86 18922482175 (WhatsApp/WeChat)

📧 Email: sarah@crusherlm.com

🏢 Address: No. 152 Xingye Road, Longxing Village, Aotou Town, Conghua District, Guangzhou, China

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent