Currency

As infrastructure development and resource recycling initiatives accelerate worldwide, the demand for efficient, reliable, and energy-saving crushing equipment continues to rise. The Leimeng PFG series impact crusher, renowned for its large feed opening, high reduction ratio, and superior energy efficiency, has become a preferred choice for processing medium-hard materials across various industries. This guide provides an in-depth analysis of the PFG impact crusher's technical features, application scenarios, and selection recommendations to help users optimize their operations.

Impact crushers are widely utilized for processing materials with a Mohs hardness of 5 to 7, such as limestone, dolomite, shale, and coal gangue. The PFG series excels in delivering high-quality, cubic-shaped aggregates with low flake content, making it ideal for construction, road building, and concrete production.

While capable of handling harder materials like granite and quartzite, it's important to note that wear rates may increase, leading to higher maintenance costs. Therefore, selecting the appropriate crusher based on material hardness is crucial for cost-effective operations.

The PFG series features an expansive feed opening, accommodating larger material sizes and reducing the need for pre-processing. With a reduction ratio ranging from 30 to 50, it enables single-pass crushing, streamlining the production process and lowering equipment investment.

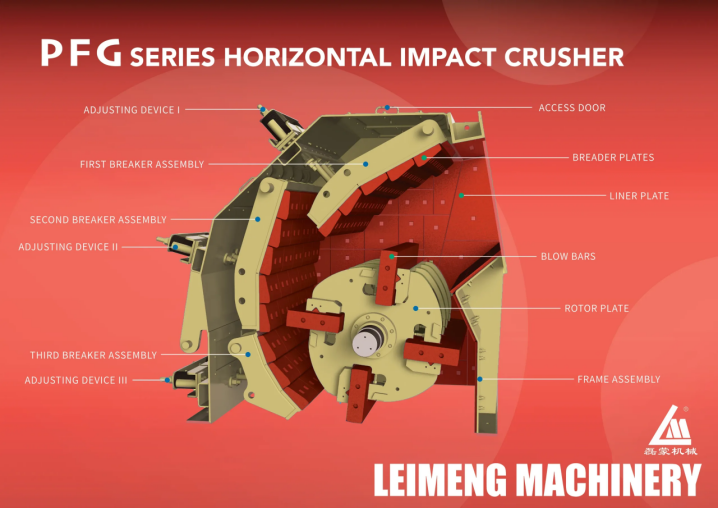

Equipped with a robust rotor design, the PFG impact crusher delivers enhanced rotational inertia and impact energy, ensuring thorough material breakage and consistent product size. The balanced rotor construction also minimizes vibration, contributing to the machine's longevity.

The multi-stage crushing chamber facilitates repeated impacts and material reorientation, resulting in well-graded, cubic-shaped aggregates with minimal flakiness. This design is particularly beneficial for producing high-quality construction materials.

The PFG series incorporates high-quality bearings and seals, resistant to temperature fluctuations and corrosion, enhancing overall machine durability. Its modular design simplifies maintenance, allowing for quick part replacements and reduced service time.

Ideal for processing medium-hard materials, the PFG impact crusher efficiently handles both primary and secondary crushing stages, optimizing production lines and reducing equipment needs.

In urban redevelopment projects, the PFG series effectively processes concrete debris and masonry, transforming waste into reusable aggregates and supporting sustainable construction practices.

For applications requiring precise aggregate shapes, such as asphalt and high-performance concrete, the PFG impact crusher delivers superior particle morphology, enhancing material performance.

Leimeng offers expert consultation to assist in selecting the most suitable PFG impact crusher for your operational needs.

The Leimeng PFG series impact crusher stands out as a versatile and efficient solution for various crushing applications. Its innovative design, durable construction, and adaptability make it an excellent choice for producing high-quality aggregates and promoting sustainable resource utilization. By selecting the appropriate model and configuration, operators can achieve optimal performance, reduced operational costs, and enhanced product quality.

For more information or to request a customized solution, please contact Leimeng's technical support team.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent