Currency

Vertical Shaft Impact (VSI) crushers have become essential equipment for producing high-quality manufactured sand and finely crushed aggregates. To maximize the efficiency and longevity of these machines, investing in custom VSI crusher wear parts is a smart choice—especially when sourced from a trusted manufacturer like Leimeng.

Generic wear parts often result in:

In contrast, customized VSI wear parts are engineered for your specific material type, feed size, and output requirements. The benefits include:

As a leader in the crushing and screening industry, Leimeng specializes in high-performance, durable wear parts built to exact specifications.

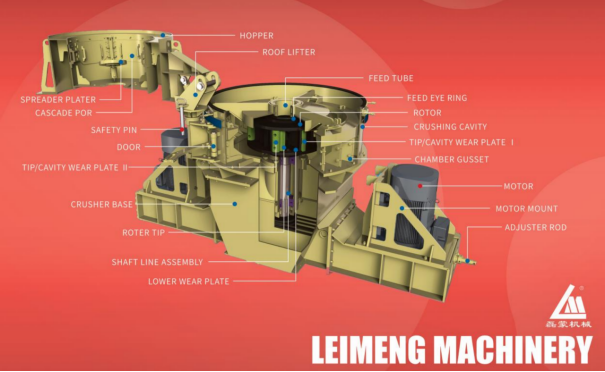

Understanding the importance of customization starts with knowing the core wear parts of a VSI crusher:

Rotor Tips – Prone to extreme wear; customized tips enhance material acceleration and impact angles.

Back-Up Tips – Reinforce the rotor tips and reduce breakage risk.

Feed Eye Ring – Protects the rotor from premature wear caused by inconsistent feed.

Cavity Wear Plates – Shield the inner walls of the crushing chamber.

Distributor Cone – Evenly distributes material inside the rotor.

Anvils & Shoes – Crucial components depending on your crushing configuration (rock-on-rock or rock-on-steel).

With custom VSI crusher wear parts, all components are designed to work in harmony, reducing vibration and preventing uneven wear.

As a premium Chinese brand, Leimeng offers advanced customization based on:

Leimeng’s R&D team uses 3D scanning, CAD design, and metallurgical analysis to ensure each component meets your precise operational needs.

Not all materials perform equally. Leimeng provides a range of materials to suit different wear environments:

High-Chrome Iron – Ideal for high-impact, low-abrasion conditions

Tungsten Carbide Inserts (TCI) – Offers extreme abrasion resistance

Martensitic Steel – Balances toughness and hardness

Ceramic Composite Coating – Reduces thermal fatigue and surface erosion

These options allow you to customize your VSI wear parts beyond what generic alternatives can offer.

Precision Engineering – Every part is scanned and prototyped before production

Extended Lifespan – Fewer replacements, less downtime

Global Compatibility – Works with various VSI models worldwide

OEM & ODM Services – Available for both large-scale parts and full system upgrades

Fast Delivery & Support – Global distribution with technical after-sales support

Leimeng not only manufactures parts but also evaluates your entire crushing system for performance enhancement opportunities.

Custom VSI crusher wear parts from Leimeng are ideal for:

Where precision and consistency are critical, Leimeng ensures your VSI setup operates with minimal deviation and material loss.

A sand and gravel facility reported frequent downtimes and severe rotor wear while using standard wear parts. After switching to Leimeng’s customized VSI wear parts, the plant saw:

This real-world example highlights the ROI of customization with a reliable partner like Leimeng.

Q: How often should I replace VSI wear parts?

A: It depends on your material's abrasiveness and operating hours. With custom parts from Leimeng, replacement frequency is significantly reduced.

Q: Can I order samples or trial parts before a full rollout?

A: Yes, Leimeng offers trial orders for OEM partners and bulk buyers.

For any business that relies on VSI crushing technology, investing in custom VSI crusher wear parts can be a game-changer. Not only will you boost performance and efficiency, but you'll also save significantly on downtime and maintenance. Partner with Leimeng, and get wear parts that are precise, durable, and performance-driven.

🌐 Website: www.lmcrusher.com

📞 Tel/WhatsApp/WeChat: +86 18922482175

📧 Email: sarah@crusherlm.com

🏢 Address: No. 152 Xingye Road, Longxing Village, Aotou Town, Conghua District, Guangzhou, China

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent