Currency

In modern mining and manufactured sand production lines, choosing the right crushing equipment is critical to improving operational efficiency and reducing energy consumption. As a commonly used medium and fine crushing device, the double roller crusher is favored by many users in the aggregate and coal industries due to its compact structure, stable operation, and controllable particle size. It performs particularly well when handling brittle and medium-hard materials such as limestone, coal, and slag.

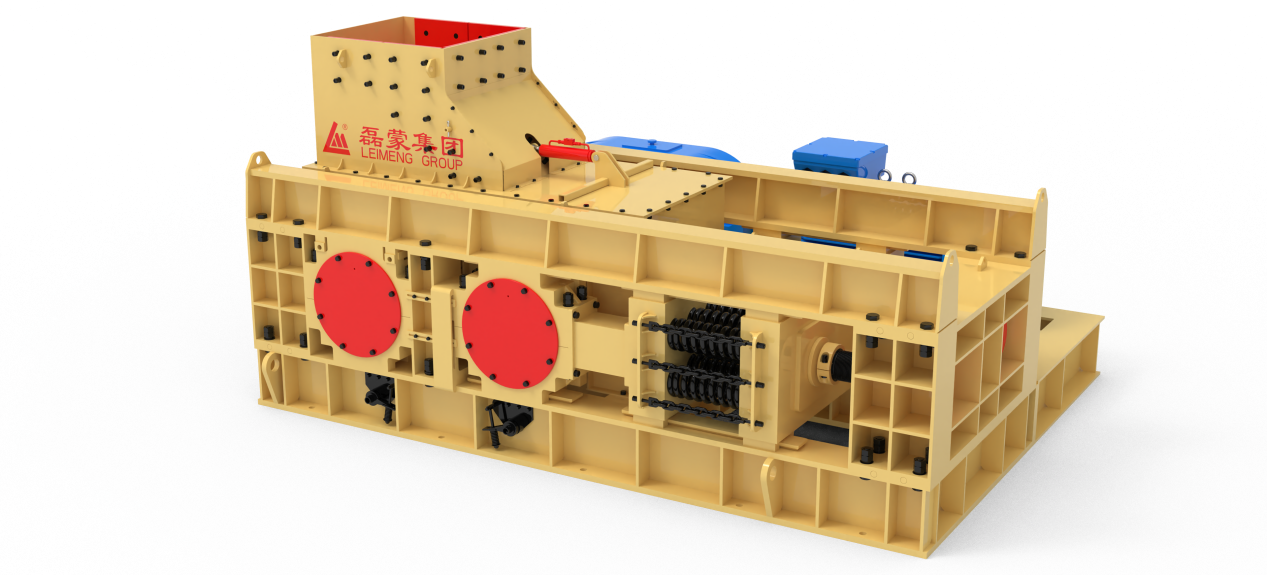

The 2PG series double roller crusher developed by Leimeng builds on traditional structural advantages, featuring optimized design and upgraded performance to enhance both adaptability and reliability.

The double roller crusher is mainly used for medium and fine crushing of materials with low to medium hardness. It is suitable for industries such as building materials, chemicals, metallurgy, power, and coal, and is widely used in the following scenarios:

Compared to jaw crushers and cone crushers, double roller crushers offer irreplaceable advantages in scenarios where moderate particle shape, low dust generation, and cost-effective operation are key requirements.

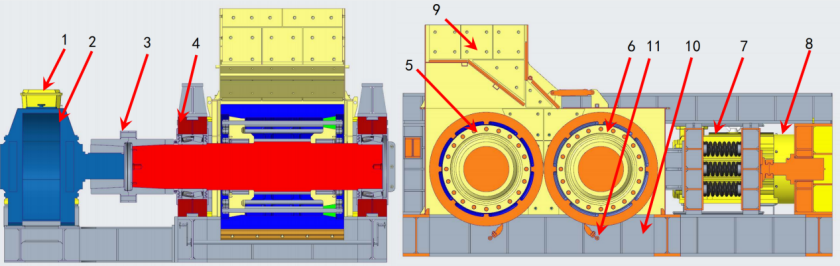

The 2PG series double roller crusher by Leimeng is made up of several key components and is designed for efficiency and compactness:

Leimeng's double roller crusher adopts a mechanical compression crushing principle, where two rollers rotate in opposite directions, creating strong compressive force between them. Materials fed from the top fall between the rollers and are crushed through continuous high-pressure compression, shearing, and splitting.

Once inside the compression zone between the rollers, the material is gradually crushed to the target particle size. Microcracks and fracture surfaces form within the particles due to the applied pressure, leading to effective fragmentation. Crushed material is then discharged naturally from the bottom.

In real-world operations, feed materials may contain uncrushable items such as metal blocks, concrete debris, or ultra-hard ores. If not addressed, these can cause the equipment to jam or even lead to roller damage or machine failure.

To prevent such risks, Leimeng’s double roller crusher integrates spring-based or hydraulic overload protection systems, providing proactive safety measures.

During normal operation, the rollers maintain a fixed compression gap to ensure steady crushing. When uncrushable material enters the crushing chamber, the overload protection system automatically activates, reducing the compressive force and allowing the rollers to move slightly apart. This creates enough clearance for the foreign object to pass through safely.

Two configurations are available based on application needs:

Leimeng’s 2PG series double roller crusher has been significantly improved in design and performance. Its core advantages include:

The 2PG series has a compact overall footprint, making it suitable for small to medium-sized crushing sites. It can also be easily integrated into existing production line upgrades.

Thanks to its simple structure and replaceable wear parts, the crusher requires minimal maintenance. Component replacement is fast and easy, helping reduce long-term operating costs.

The gap between the rollers can be adjusted to achieve precise control over output particle size. This flexibility is especially valuable for manufactured sand plants or applications with moderate particle shape requirements.

The low noise level during operation makes the equipment suitable for environmentally friendly production lines, aligning with modern standards of energy conservation and emission reduction.

Leimeng offers a range of models to meet various customer needs:

| Model | Roller Diameter (mm) | Roller Length (mm) | Max Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kW) | Dimensions (mm) |

| 2PG1206 | 1200 | 600 | ≤40 | <5 | 150–230 | 250 | 5000×2800×2550 |

| 2PG1210 | 1200 | 1000 | ≤40 | <5 | 150–300 | 315 | 5000×3600×2550 |

| 2PG1510 | 1500 | 1000 | ≤50 | <5 | 200–400 | 450 | 5700×3600×3050 |

| 2PG1515 | 1500 | 1500 | ≤50 | <5 | 335–600 | 630 | 5700×4600×3050 |

Project Background: 1 million tons/year construction aggregate project. The original system had high dust levels and frequent maintenance issues.

Solution: Replaced the hammer crusher with one unit of Leimeng 2PG1210 double roller crusher.

Results:

Leimeng adheres to the philosophy of “Technology-driven, Serving the World,” aiming to provide high-efficiency, intelligent, and eco-friendly crushing and screening solutions for global customers.

Technical Support: Professional model selection advice and customized crushing solutions

After-Sales Service: Easy maintenance with readily available spare parts

Fast Delivery: Short lead times and responsive support to keep your project on schedule

High Cost-Performance Ratio: Competitive pricing without compromising on quality

As infrastructure development and resource recycling continue to advance, there is a growing demand for more efficient and economical crushing equipment. With its mature structure, low energy consumption, and controllable discharge size, the Leimeng 2PG series double roller crusher has become the ideal choice for many industrial customers.

If you’re looking for a reliable, energy-saving, and stable solution for medium and fine crushing, Leimeng’s double roller crusher is a choice you can trust.

For detailed model selection advice and pricing information, please contact the Leimeng technical team. We are here to provide you with professional support.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent